Density: 8.22 g/cm³

Equivalent designations:

Hastelloy G-35 Alloy, UNS N06035, DIN W.Nr 2.4643, Alloy G-35

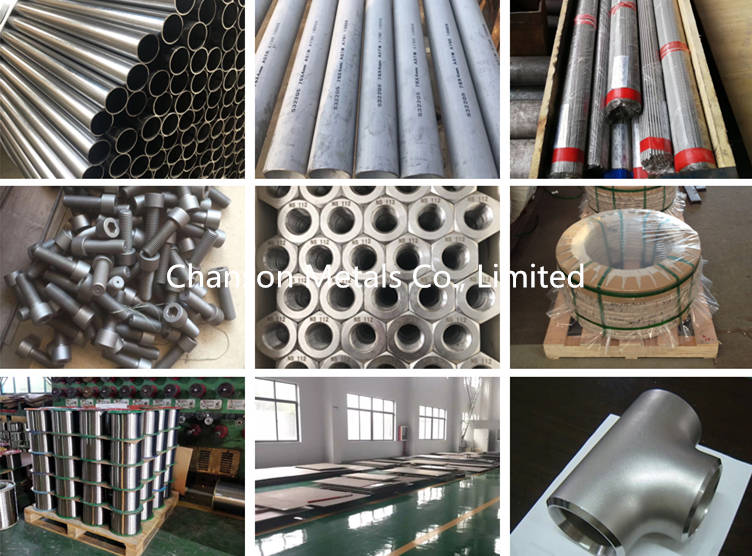

Available products: pipe,tube,bar,rod,wire,sheet,strip,fastener,flange,pipe fittings

Hastelloy G-35 is a nickel-chrimium-molybdenum alloy designed to resist “wet process” phosphoric acid, which is used in the production of fertilizers. Similar to Hastelloy G-30, G35 alloy also has excellent resistance to localized attack in the presence of chlorides, since this can be a problem beneath deposits in evaporators used to concentrate “wet process” phosphoric acid. Besides, it is much less susceptible to chloride-induced stress corrosion cracking than the stainless steels and nickel-chromium-iron alloys traditionally used in “wet process” phosphoric acid. Due to the high chromium content, Hastelloy G-35 is extremely resistant to other oxidizing acids, such as nitric, and mixtures containing nitric acid. It possesses moderate resistance to reducing acids, as a result of its appreciable molybdenum content, and, unlike other Ni-Cr-Mo alloys, it is very resistant to “caustic de-alloying” in hot sodium hydroxide.

Chemical composition:

| Grade | Componente químico % | |||||||||||||

| Ni | Cr | Mo | W | Fe | Mn | C | Si | S | P | Co | Cu | V | Al | |

| Hastelloy G-35 | Bal | 32.25-34.25 | 7.6-9.0 | Max 0.6 | Max 2.0 | Max 0.5 | Max 0.05 | Max 0.6 | Max 0.015 | Max 0.3 | Max 1.0 | Max 0.3 | Max 0.2 | Max 0.3 |

Available products for Hastelloy G35:

Welded pipe/tube

Seamless pipe/tube

Pipe fittings

Flanges

Bar/Profiles

Sheet/ Plate/Coil/Strip

Wire/Wire rope

Forgings

Welding Rod

Fastener

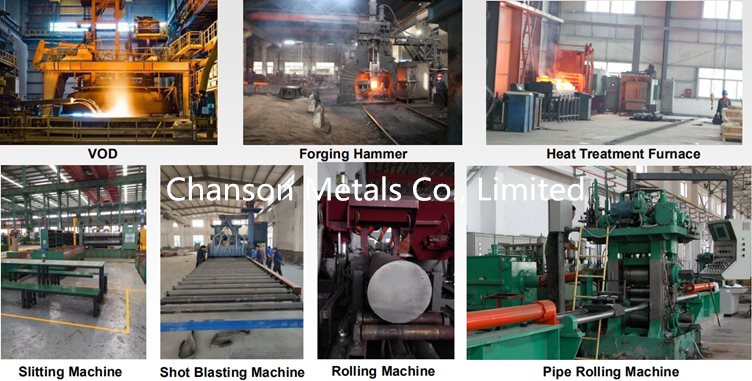

Our Equipments:

Test:

Packing: Anti-wet bag,wooden box,wooden pallet or as required.