Hastelloy B-2/B3

Density: 9.22g/cm³

Equivalent designations: Hastelloy B-2, Alloy B2, UNS N10665, W.Nr. 2.4617

Hastelloy B-3 Alloy, UNS N10675, W. Nr. 2.4600

Available products: pipe,tube,bar,rod,wire,sheet,strip,fastener,flange,pipe fittings

Product introduction

Hastelloy B2 is a solid solution strengthened, nickel-molybdenum alloy, has outstanding resistance to hydrochloric acid at all concentrations and temperatures,with significant resistance to reducing environments like hydrogen chloride gas, and sulfuric, acetic and phosphoric acids. In additions, Hastelloy B2 has excellent resistance to pitting, stress corrosion cracking and to knife-line and heat-affected zone attack.

HASTELLOY B-3 alloy (UNS N10675) exhibits extremely high resistance to pure hydrochloric, hydrobromic, and sulfuric acids. Furthermore, it has greatly improved structural stability compared with previous B-type alloys, leading to fewer concerns during welding, fabrication, and service.

Chemical composition:

2. Vacuum furnaces

3. Mechanical components

HASTELLOY B-3 alloy (UNS N10675) exhibits extremely high resistance to pure hydrochloric, hydrobromic, and sulfuric acids. Furthermore, it has greatly improved structural stability compared with previous B-type alloys, leading to fewer concerns during welding, fabrication, and service.

Chemical composition:

|

Grado

|

Componente químico % | ||||||||||||||||||

| C | Si | Mn | S | P | Ni | Cr | Mo | Fe | Co | Ni+Mo | V | Cu | Al | Ti | Nb | W | Ta | Zr | |

| Hastelloy B-2 | Max 0.02 | Max 0.1 | Max 1.0 | Max 0.03 | Max 0.04 | Bal | Max 1.0 | 26.0-30.0 | Max 2.0 | Max 1.0 | |||||||||

| HastelloyB-3 | Max 0.01 | Max 0.1 | Max 3.0 | Max 0.01 | Max 0.03 | Min 65.0 | 1.0-3.0 | 27.0-32.0 | 1.0-3.0 | Max 3.0 | 94.0-98.0 | Max 0.2 | Max 0.2 | Max 0.5 | Max 0.2 | Max 0.2 | Max 3.0 | Max 0.2 | Max 0.01 |

Application:

1. Chemical process applications2. Vacuum furnaces

3. Mechanical components

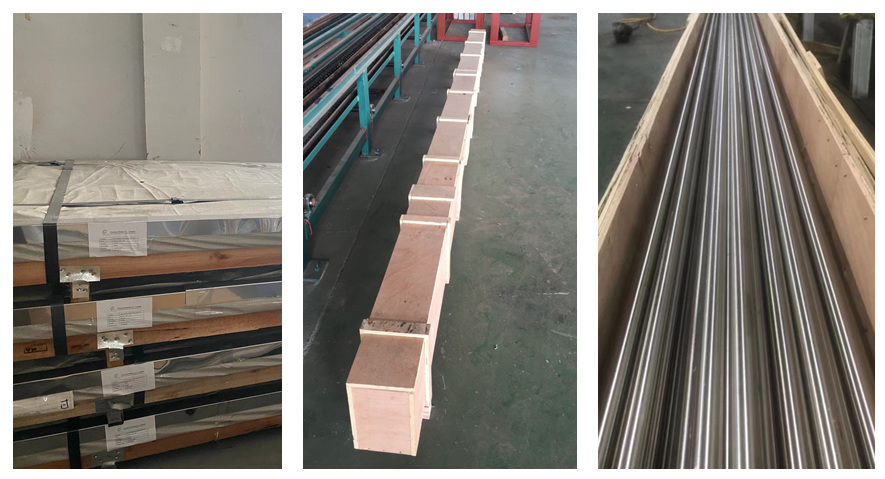

Cargo packaging: