Equivalent designations:

INCONEL 601, ALLOY 601, UNS N06601, DIN W. NR. 2.4851

Product Types Available

We offer Inconel 601 in a variety of forms to suit your specific application needs:

Sheets and Plates: Available in various thicknesses for use in structural applications and heat exchangers.

Bars and Rods: Suitable for manufacturing components that require high strength and resistance to corrosion and heat.

Pipes and Tubes: Ideal for chemical processing and power generation applications.

Wires: Used in high-temperature and high-corrosion environments.

Forgings: Custom shapes and sizes for specific industrial requirements.

Inconel 601 is a premium nickel-chromium alloy renowned for its outstanding resistance to oxidation and high-temperature corrosion. This alloy combines excellent mechanical strength and ease of fabrication, making it ideal for a wide range of demanding industrial applications.

An important property of Alloy 601 is its ability to resist oxidation at temperatures up to 1180 °C. Even under very harsh conditions, such as heating and cooling cycles, 601 can form a dense oxide film with high resistance to spalling. 601 has good resistance to carbonization. Due to its high chromium and aluminum content, 601 has excellent oxidation resistance in high temperature sulfur-containing atmospheres.

Chemical Composition of Inconel 601

| Element | Composition (%) |

| Nickel (Ni) | 58 - 63 |

| Chromium (Cr) | 21 - 25 |

| Iron (Fe) | Balance |

| Aluminum (Al) | 1.0 - 1.7 |

| Silicon (Si) | 0.5 max |

| Manganese (Mn) | 1.0 max |

| Copper (Cu) | 1.0 max |

| Carbon (C) | 0.10 max |

| Sulfur (S) | 0.015 max |

Physical Properties of Inconel 601

| Property | Value |

| Density | 8.11 g/cm³ |

| Melting Range | 1360 - 1411℃ (2480 - 2571℉) |

| Tensile Strength | 655 MPa (95 ksi) (Min) |

| Yield Strength (0.2% Offset) | 310 MPa (45 ksi) (Min) |

| Elongation | 30% (Min) |

| Hardness | Rb 90 (Max) |

Products standard:

ASTM B166

AMS 5665

Din 17752

ASTM B168

AMS 5540

Din 17750

ASTM B516/B517

ASTM B775/B751

ASTM B56

Din 17754

Products

Bar,rod,wire

Sheet,Plate,strip

Welded tube/pipe

Seamless tube/pipe

Fitting

Forging

Standard

ASTM B167

ASTM B366

Why Choose Inconel 601 from Chanson Metals?

1. Superior Oxidation and Corrosion Resistance

Inconel 601 is engineered to provide excellent resistance to oxidation and a variety of corrosive environments, including those with high temperatures and severe conditions. This makes it perfect for applications requiring long-term service at elevated temperatures.

2. Exceptional High-Temperature Performance

Inconel 601 maintains its mechanical strength and structural stability at temperatures up to 2200°F (1200°C), making it suitable for high-temperature environments such as thermal processing and power generation.

3. Versatility and Fabricability

Inconel 601 can be easily fabricated using standard manufacturing techniques, including welding, machining, and forming. This versatility allows us to produce a wide range of components tailored to your specific needs.

4. Stringent Quality Control

At Chanson Metals, quality is our top priority. Our production process for Inconel 601 includes rigorous quality control measures to ensure that every batch meets the highest industry standards. We employ advanced testing methods to verify the alloy's chemical composition, mechanical properties, and corrosion resistance.

Applications of Inconel 601

Our Inconel 601 is trusted by leading companies across various industries for its unmatched performance and reliability:

1. Aerospace: Engine components, turbine blades, and exhaust systems.

2. Chemical Processing: Heat exchangers, reactors, and piping systems exposed to corrosive media.

3. Power Generation: Components in gas and steam turbines, and nuclear reactors.

4. Thermal Processing: Furnace components and high-temperature fixtures.

5. Marine: Equipment and structures exposed to seawater and harsh marine environments.

Product Types Available

We offer Inconel 601 in a variety of forms to suit your specific application needs:

1. Sheets and Plates: Available in various thicknesses for use in structural applications and heat exchangers.

2. Bars and Rods: Suitable for manufacturing components that require high strength and resistance to corrosion and heat.

3. Pipes and Tubes: Ideal for chemical processing and power generation applications.

4. Wires: Used in high-temperature and high-corrosion environments.

5. Forgings: Custom shapes and sizes for specific industrial requirements.

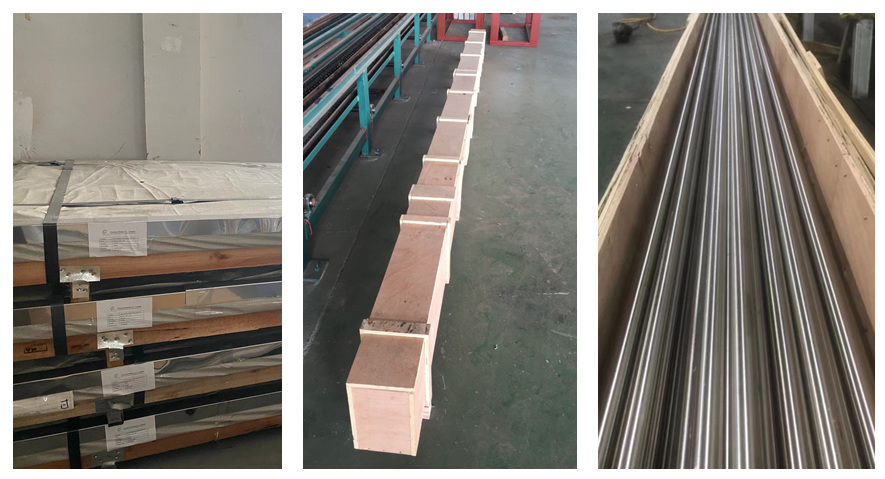

Cargo packaging:

Contact us now to learn more about our Inconel 601 products and how we can support your projects with the highest quality nickel-chromium alloy solutions. Trust Chanson Metals for all your high-performance material needs.