Equivalent designations:

Nickel Alloy 690, UNS N06690, WNR 2.4642

Product Types Available

We offer Inconel 690 in a variety of forms to suit diverse industrial applications:

Sheets and Plates: For structural components and heat exchangers.

Bars and Rods: Ideal for high-strength applications.

Pipes and Tubes: Suitable for corrosive chemical processing environments.

Wires: Used in high-temperature and high-corrosion applications.

Forgings: Customized shapes and sizes for specialized needs.

Chemical Composition of Inconel 690

| Element | Composition (%) |

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 27.0 - 31.0 |

| Iron (Fe) | 7.0 - 11.0 |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Copper (Cu) | 0.50 max |

| Carbon (C) | 0.05 max |

| Sulfur (S) | 0.015 max |

Physical Properties of Inconel 690

| Property | Value |

| Density | 8.19 g/cm³ |

| Melting Range | 1343 - 1377℃ (2450 - 2510℉) |

| Tensile Strength | 586 MPa (85 ksi) (Min) |

| Yield Strength (0.2% Offset) | 241 MPa (35 ksi) (Min) |

| Elongation | 30% (Min) |

| Hardness | Rb 90 (Max) |

Production Standards

Our Inconel 690 products are manufactured in compliance with the following international standards to ensure superior quality and performance:

ASTM B167: Standard Specification for Nickel-Chromium-Iron Alloy (UNS N06690) Seamless Pipe and Tube

ASTM B168: Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06690) Plate, Sheet, and Strip

ASTM B163: Standard Specification for Nickel-Chromium-Iron Alloy (UNS N06690) Seamless Tubes for Condensers and Heat Exchangers

ASME SB-167: Seamless Nickel-Chromium-Iron Alloy Pipe and Tube

Why Choose Inconel 690 from Chanson Metals?

1. Superior Oxidation and Corrosion Resistance

Inconel 690 offers outstanding resistance to a wide range of corrosive environments, including hot gases and oxidizing acids. Its exceptional oxidation resistance at high temperatures makes it suitable for extreme operating conditions.

2. Exceptional High-Temperature Performance

With remarkable stability and mechanical strength at elevated temperatures, Inconel 690 maintains its properties up to 2200°F (1204°C). This makes it highly suitable for applications in aerospace, chemical processing, and power generation industries.

3. Versatility and Fabricability

Inconel 690 can be easily fabricated using standard manufacturing techniques, including welding, machining, and forming. This versatility allows us to produce a variety of components tailored to meet specific customer requirements.

4. Stringent Quality Control

At Chanson Metals, quality is our top priority. Our Inconel 690 products undergo rigorous quality control measures to ensure they meet or exceed the highest industry standards. We employ advanced testing methods to verify the alloy's chemical composition, mechanical properties, and corrosion resistance.

Applications of Inconel 690

Inconel 690 is trusted by leading companies across various industries for its unmatched performance and reliability:

1. Aerospace: Engine components, turbine blades, and exhaust systems.

2. Chemical Processing: Heat exchangers, reactors, and piping systems exposed to corrosive media.

3. Power Generation: Components in gas and steam turbines, and nuclear reactors.

4. Thermal Processing: Furnace components and high-temperature fixtures.

5. Marine: Equipment and structures exposed to seawater and harsh marine environments.

Product Types Available

We offer Inconel 690 in a variety of forms to suit diverse industrial applications:

Sheets and Plates: For structural components and heat exchangers.

Bars and Rods: Ideal for high-strength applications.

Pipes and Tubes: Suitable for corrosive chemical processing environments.

Wires: Used in high-temperature and high-corrosion applications.

Forgings: Customized shapes and sizes for specialized needs.

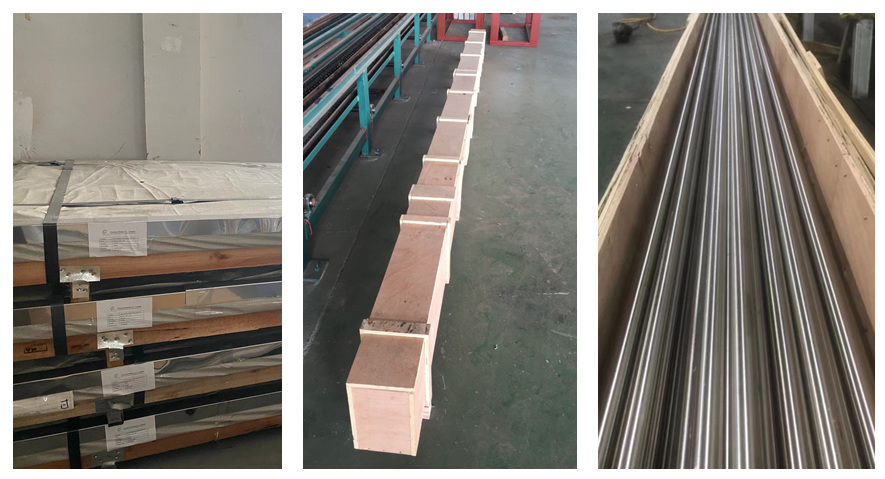

Cargo packaging:

Contact Chanson Metals today to explore how Inconel 690 can elevate your projects with its superior performance and reliability. Trust us for premium nickel alloy solutions tailored to meet your specific needs.