Equivalent designations:

INCONEL alloy 718,UNS N07718, W.Nr. 2.4668

Product Types Available

We offer Inconel 718 in various forms to meet diverse industrial applications:

Sheets and Plates: For structural applications and heat exchangers.

Bars and Rods: Ideal for high-strength components.

Pipes and Tubes: Suitable for high-temperature and high-pressure environments.

Wires: Used in high-stress and high-temperature applications.

Forgings: Custom shapes and sizes for specific industrial needs.

Inconel 718 is a versatile nickel-chromium alloy known for its exceptional mechanical properties and resistance to extreme environments. Inconel 718 is ideal for a wide range of applications, offering excellent performance in high-stress and high-temperature environments.

Chemical Composition of Inconel 718

Element

Composition (%)

Nickel (Ni)

50.0 - 55.0

Chromium (Cr)

17.0 - 21.0

Iron (Fe)

Balance

Columbium (Nb) + Tantalum (Ta)

4.75 - 5.50

Molybdenum (Mo)

2.80 - 3.30

Titanium (Ti)

0.65 - 1.15

Aluminum (Al)

0.20 - 0.80

Cobalt (Co)

1.0 max

Manganese (Mn)

0.35 max

Silicon (Si)

0.35 max

Carbon (C)

0.08 max

Copper (Cu)

0.30 max

Boron (B)

0.006 max

Sulfur (S)

0.015 max

Phosphorus (P)

0.015 max

Physical Properties of Inconel 718

Property

Value

Density

8.19 g/cm³

Melting Range

1260 - 1336℃ (2300 - 2437℉)

Tensile Strength

965 MPa (140 ksi) (Min)

Yield Strength (0.2% Offset)

550 MPa (80 ksi) (Min)

Elongation

12% (Min)

Hardness

Rb 100 (Max)

Production Standards

Our Inconel 718 products adhere to the following international standards to ensure the highest quality and performance:

ASTM B637

Standard Specification for Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock for High-Temperature Service

ASTM B670

Standard Specification for Precipitation-Hardening Nickel Alloy Plate, Sheet, and Strip

ASTM B983

Standard Specification for Precipitation-Hardening or Cold Worked, Seamless Nickel Alloy Pipe and Tube

AMS 5662

Aerospace Material Specification for Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings

AMS 5663

Aerospace Material Specification for Nickel Alloy, Corrosion and Heat-Resistant, Wire, Drawn, or Cold Finished

Why Choose Inconel 718 from Chanson Metals?

1. Exceptional Mechanical Properties

Inconel 718 provides high tensile strength, creep-rupture strength, and fatigue resistance, making it suitable for demanding applications in aerospace, power generation, and other critical industries.

2. Outstanding Corrosion and Oxidation Resistance

With excellent resistance to oxidation and corrosion in a variety of environments, Inconel 718 ensures longevity and reliability in harsh conditions.

3. Excellent Fabrication Characteristics

Inconel 718 is readily fabricated, including machining and welding, and can be easily formed into complex shapes, allowing for the production of customized components.

4. Strict Quality Control

At Chanson Metals, we prioritize quality and consistency. Our Inconel 718 products undergo stringent quality control measures to ensure they meet or exceed industry standards, guaranteeing superior performance and reliability.

Product Types Available

We offer Inconel 718 in various forms to meet diverse industrial applications:

Sheets and Plates: For structural applications and heat exchangers.

Bars and Rods: Ideal for high-strength components.

Pipes and Tubes: Suitable for high-temperature and high-pressure environments.

Wires: Used in high-stress and high-temperature applications.

Forgings: Custom shapes and sizes for specific industrial needs.

Applications of Inconel 718

Inconel 718 is trusted across various industries for its unmatched performance:

1. Aerospace: Engine components, turbine blades, fasteners.

2. Power Generation: Gas turbines, nuclear reactors.

3. Chemical Processing: Heat exchangers, reactor components.

4. Oil and Gas: Downhole equipment, valves, fasteners.

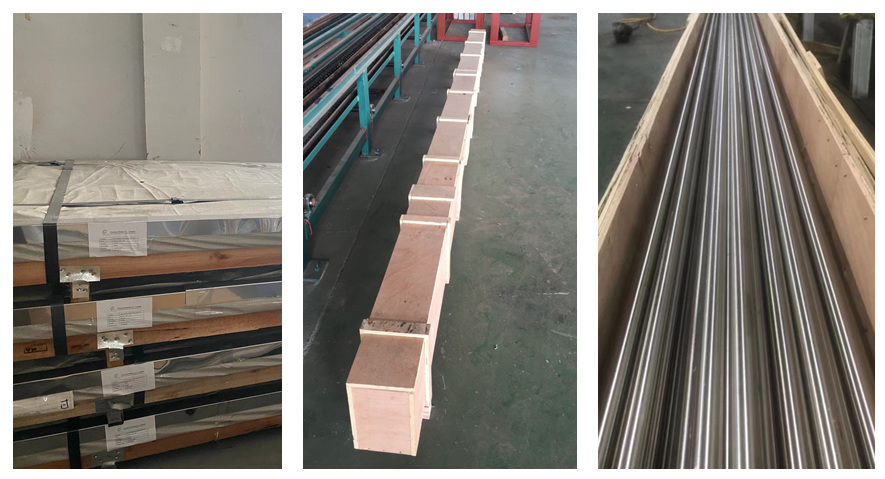

Cargo packaging:

Contact Chanson Metals today to discover how Inconel 718 can enhance your projects with its superior performance and reliability. Trust us for premium nickel alloy solutions tailored to your specific needs.