Nimonic C-263

Density: 8.36 g/cm³

Equivalent designations:

Nimonic C-263, Alloy 263, UNS N07263, Nickle Alloy 263, DIN W.NR 2.4650

Available products:

pipe,tube,bar,rod,wire,sheet,strip,bolt and nut,flange,pipe fittings

Product introduction

Nimonic 263 is an age-hardenable nickel-cobalt chromium-molybdenum alloy designed specifically to combine good aged strength properties with excellent fabrication characteristics in the annealed condition. While its strength at elevated temperatures is not quite as high as Waspaloy or Rene 41, it is far easier to form or weld than these alloys. Alloy C263 plate - Nimonic 263 plate exhibits excellent intermediate temperature tensile ductility, and is not normally subject to strain age cracking problems common for other gamma prime strengthened alloys. This grade is typically used for applications up to about 1650°F (900°C). This grade combines properties which make it suitable for a variety of fabricated components in both aircraft turbine engine and landbased turbine applications.

Chemical composition:

Application:

1. gas turbines such as combustion chambers, casings, liners, exhaust ducting and bearing housings

2. thick section pipe in high temperature steam power plant

Chemical composition:

| Grade | Componente químico % | ||||||||||||||||

| C | Si | Cu | Fe | Mn | Ni | Cr | Co | Mo | Al | B | S | Ag | Ti | Al+Ti | B i | Pb | |

| Nimonic 263 | 0.04-0.08 | Max 0.4 | Max 0.2 | Max 0.7 | Max 0.6 | EQUILIBRAR | 19.0-21.0 | 19.0-21.0 | 5.6-6.1 | Max 0.6 | Max 0.005 | Max 0.007 | Max 0.0005 | 1.9-2.4 | 2.4-2.8 | Max 0.0001 | Max 0.002 |

1. gas turbines such as combustion chambers, casings, liners, exhaust ducting and bearing housings

2. thick section pipe in high temperature steam power plant

Available products for Nimonic C-263:

Welded pipe/tube

Seamless pipe/tube

Pipe fittings

Flanges

Bar/Profiles

Sheet/ Plate/Coil/Strip

Wire/Wire rope

Forgings

Welding Rod

Fastener

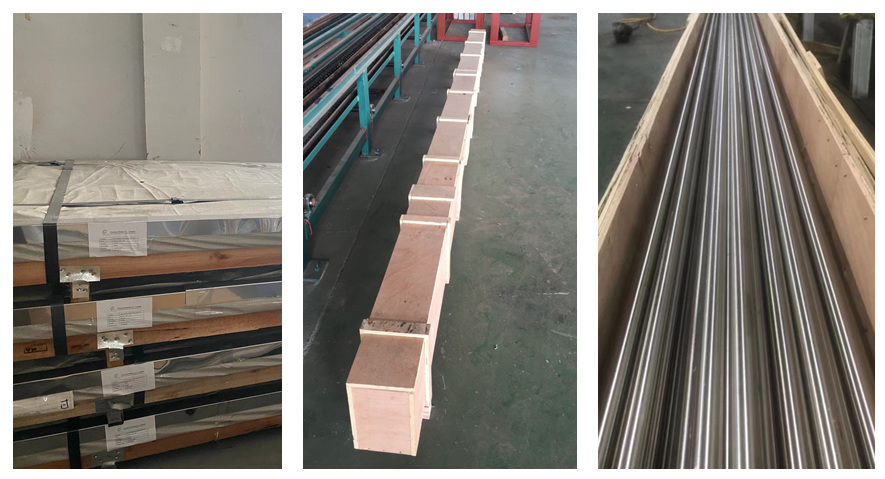

Cargo packaging: