Nitronic 50

Density: 7.83 g/cm³

Equivalent designations:

NITRONIC 50, UNS S20910,XM-19

Available products:

pipe,tube,bar,rod,wire,sheet,strip,bolt and nut,flange,pipe fittings

Product introduction

Nitronic 50 is a nitrogen-strengthened austenitic stainless steel that possesses corrosion resistance superior to 316, 316L, 317 and 317L plus approximately twice the yield strength at room temperature. It has very good mechanical properties at both elevated and sub-zero temperatures. The alloy retains low magnetic permeability even after severe cold working or exposure to sub-zero temperatures and excellent mechanical properties up to 1200°F (649°C).

Nitronic 50 provides outstanding corrosion resistance in many process streams. Annealed at 2025°F, Nitronic 50 exhibits excellent resistance to highly corrosive environments where the material will be used in the as-welded condition. It has outstanding resistance to sulfide stress cracking and to intergranular attack.

Nitronic 50 does not become magnetic when severely cold worked. This makes it useful for applications requiring a combination of excellent corrosion resistance and low magnetic permeability. Although the magnetic permeability of Nitronic 50 remains very low at cryogenic temperatures, it does not approach the levels of Nitronic 33 and Nitronic 40.

Chemical composition:

Application:

1. Marine – seawater pumps, gate valves for seawater ballast systems on tankers, high-pressure (microbial) deep-sea sampler and incubation chambers and underwater robotic arms.

2. Chemical – urea production, ammonium carbamate pumps, pressure vessels, tanks, heat exchangers, piping, fittings, valves and pumps.

3. Pump & Paper – Valves for sulfite liquors

4. Nuclear Waste Disposal – waste calcination systems, aqueous fluoride handling systems and waste canisters.

5. Oil & Gas Production – oil field production and down-hole equipment

Available products for Nitronic 50:

Welded pipe/tube

Seamless pipe/tube

Pipe fittings

Flanges

Bar/Profiles

Sheet/ Plate/Coil/Strip

Wire/Wire rope

Forgings

Welding Rod

Fastener

Nitronic 50 provides outstanding corrosion resistance in many process streams. Annealed at 2025°F, Nitronic 50 exhibits excellent resistance to highly corrosive environments where the material will be used in the as-welded condition. It has outstanding resistance to sulfide stress cracking and to intergranular attack.

Nitronic 50 does not become magnetic when severely cold worked. This makes it useful for applications requiring a combination of excellent corrosion resistance and low magnetic permeability. Although the magnetic permeability of Nitronic 50 remains very low at cryogenic temperatures, it does not approach the levels of Nitronic 33 and Nitronic 40.

Chemical composition:

| Grade | Chemical Component % | |||||||||||

| Fe | Cr | Ni | Mo | Nb | Mn | Si | C | S | P | V | N | |

| Nitronic 50 | Balance | 20.5-23.5 | 11.5-13.5 | 1.5-3.0 | 0.1-0.3 | 4.0-6.0 | Max 1.0 | Max 0.06 | Max 0.03 | Max 0.04 | 0.1-0.3 | 0.2-0.4 |

1. Marine – seawater pumps, gate valves for seawater ballast systems on tankers, high-pressure (microbial) deep-sea sampler and incubation chambers and underwater robotic arms.

2. Chemical – urea production, ammonium carbamate pumps, pressure vessels, tanks, heat exchangers, piping, fittings, valves and pumps.

3. Pump & Paper – Valves for sulfite liquors

4. Nuclear Waste Disposal – waste calcination systems, aqueous fluoride handling systems and waste canisters.

5. Oil & Gas Production – oil field production and down-hole equipment

Available products for Nitronic 50:

Welded pipe/tube

Seamless pipe/tube

Pipe fittings

Flanges

Bar/Profiles

Sheet/ Plate/Coil/Strip

Wire/Wire rope

Forgings

Welding Rod

Fastener

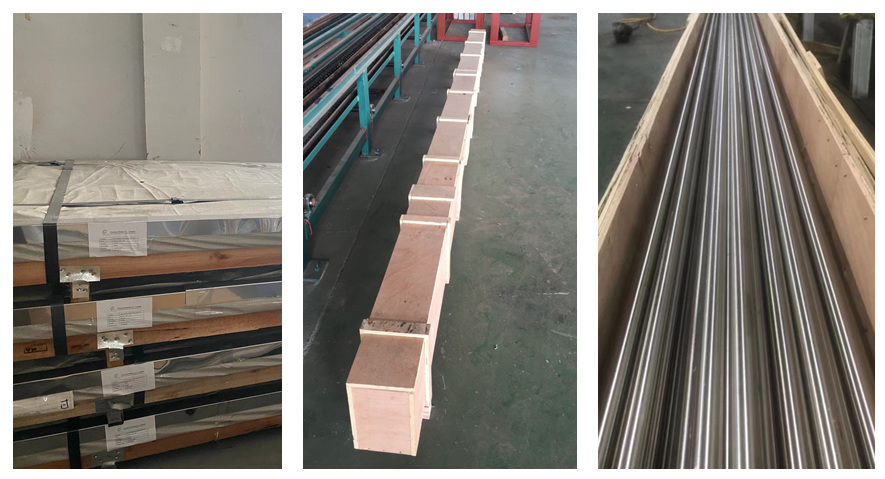

Cargo packaging: